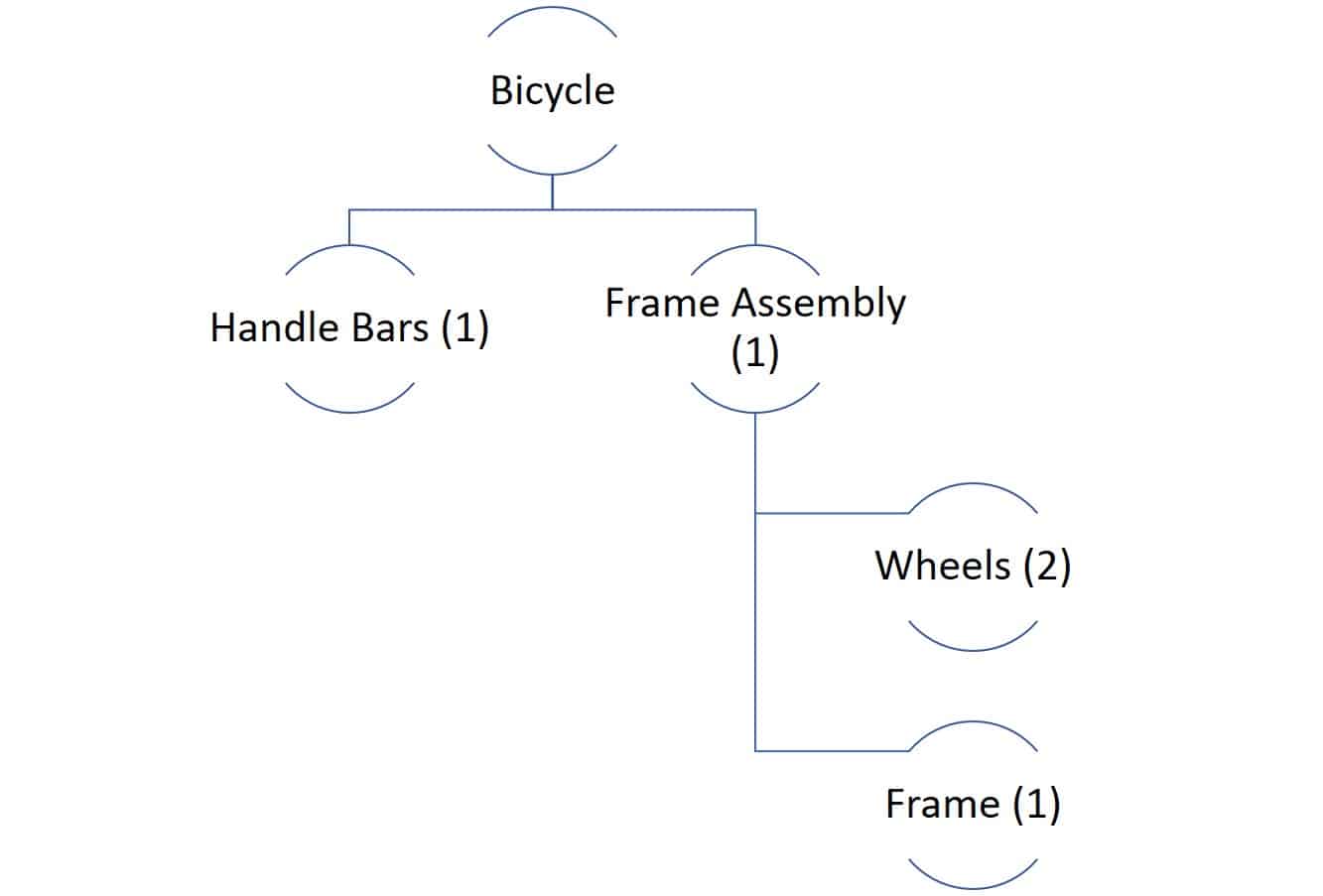

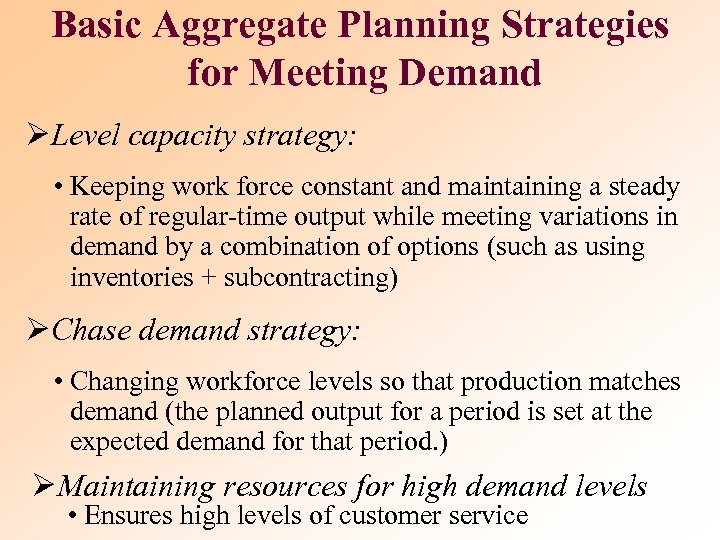

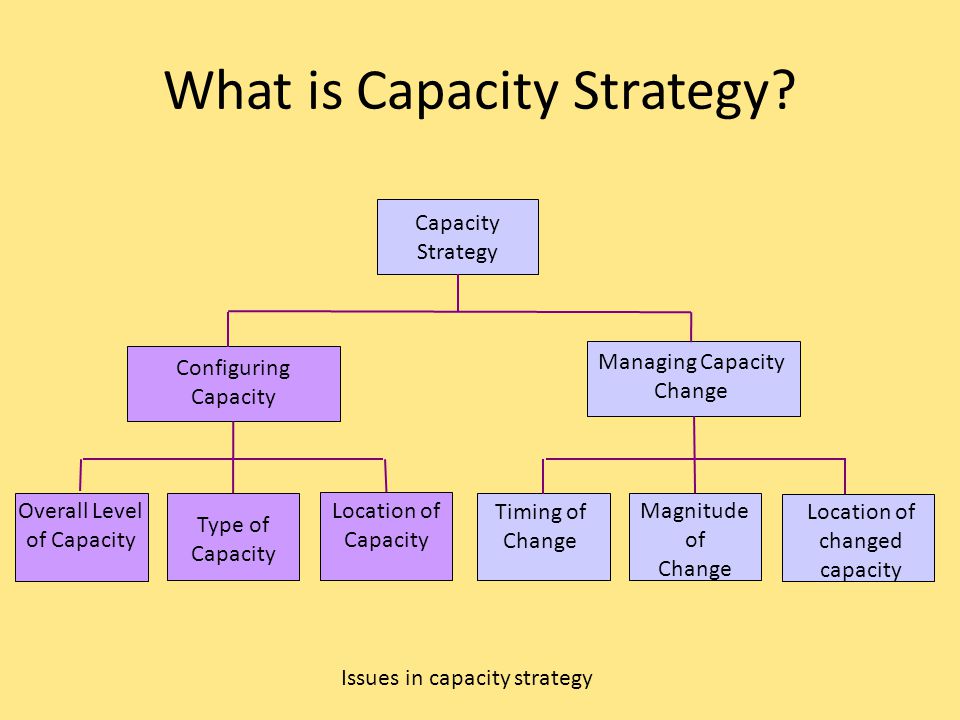

Evaluating Capacity and Liquidity for Equity Strategies How to tell when a fund has become too big Executive Summary Identifying a strategy's capacity is a key aspect of evaluating its prospects It' s one thing to identify a strategy that can do well using its current process and manager , but knowing the point at which the Capacity strategies • Lead strategythe company increases its production capacity in advance of anticipated increases in demand • Lag strategythe company responds to actual increases in demand by boosting capacity after the operation is running at full steam • Match strategythe company matches the demand and supply 13Level capacity strategy Maintaining a steady rate of regular time output while from MBA 1570 at Institute of Management Technology, Dubai

Demand And Capacity Management Options Adapted From Fitzsimmons And Download Scientific Diagram

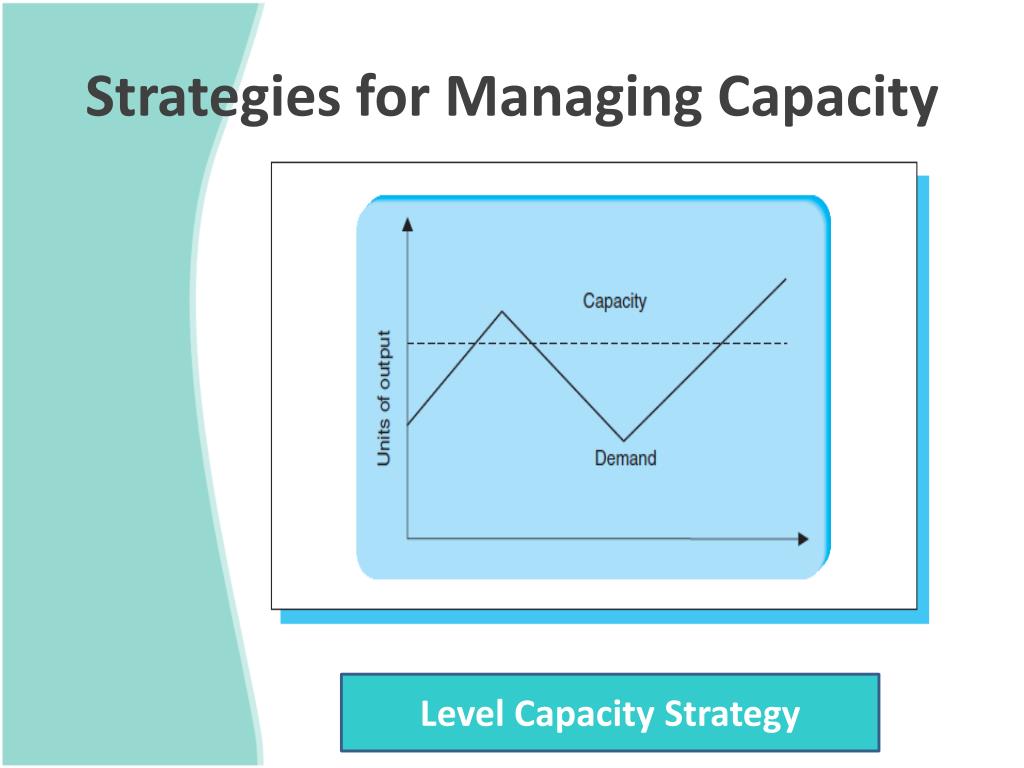

The level capacity strategy variations in demand are met

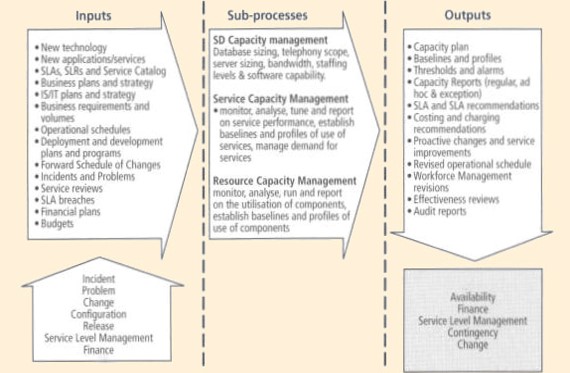

The level capacity strategy variations in demand are met-Capacity Management Level and Utilisation Capacity Management Level and Utilisation Watch later Share Copy link Info Shopping Tap to unmute If 3 Types of Capacity Management Capacity management is the process of planning the resources required to meet business demands This includes capacity forecasting, planning, monitoring and performance analysis This can happen at three levels in an organization

Multi Level Model For Building Capacity For A National Quality Download Scientific Diagram

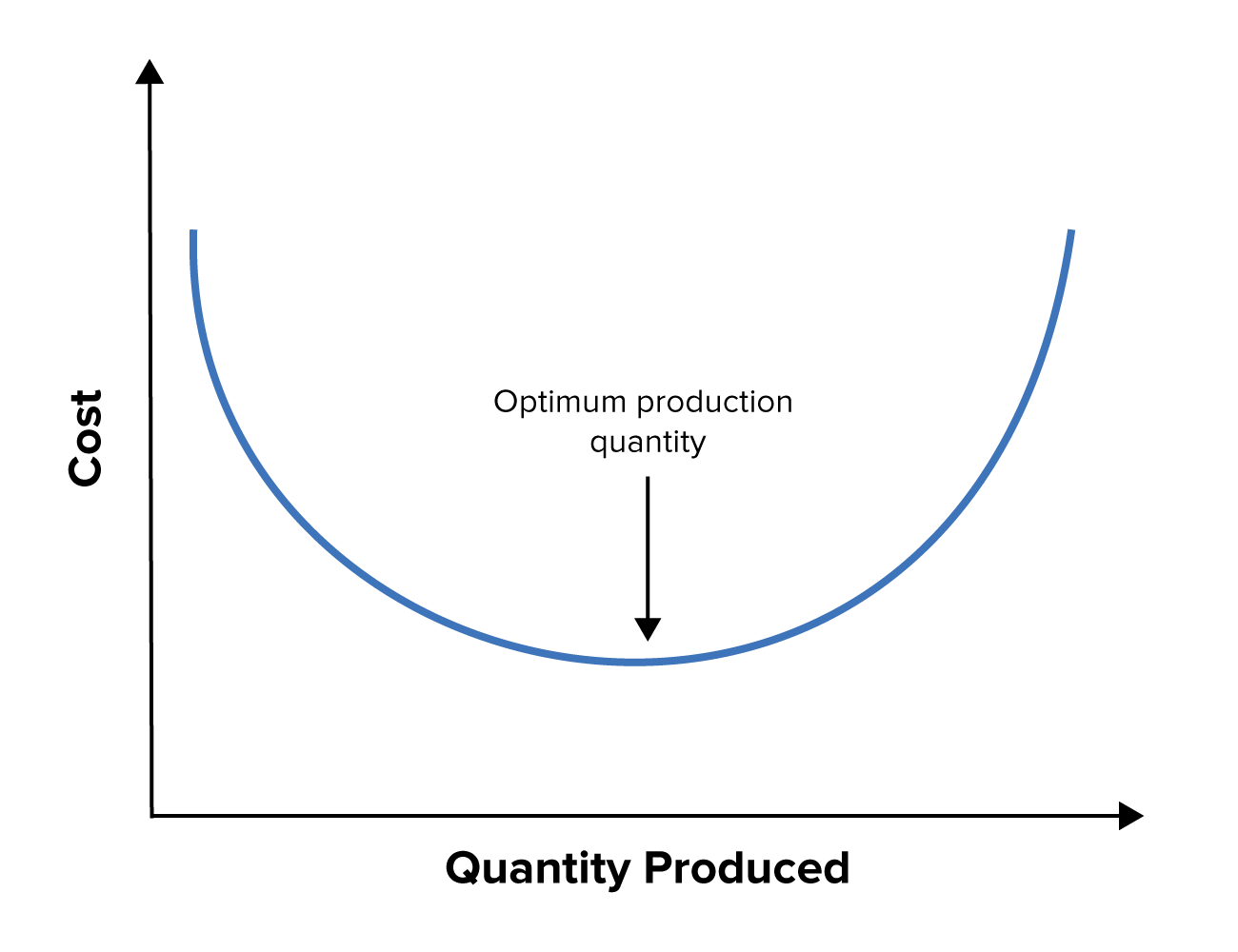

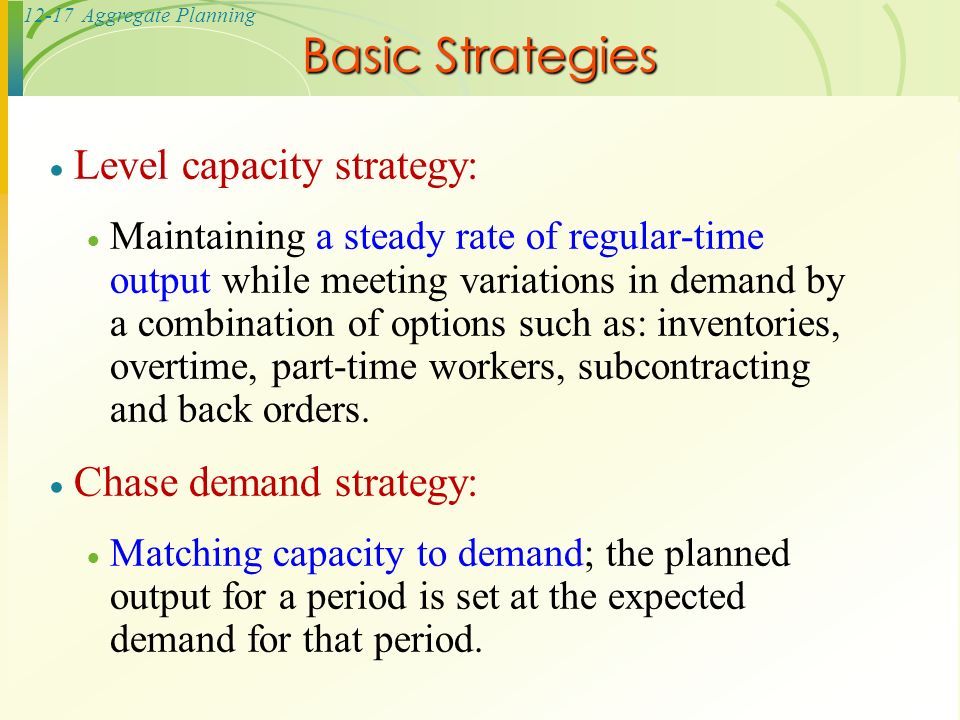

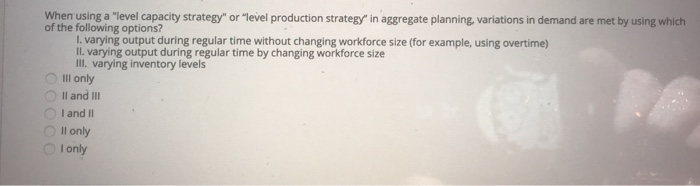

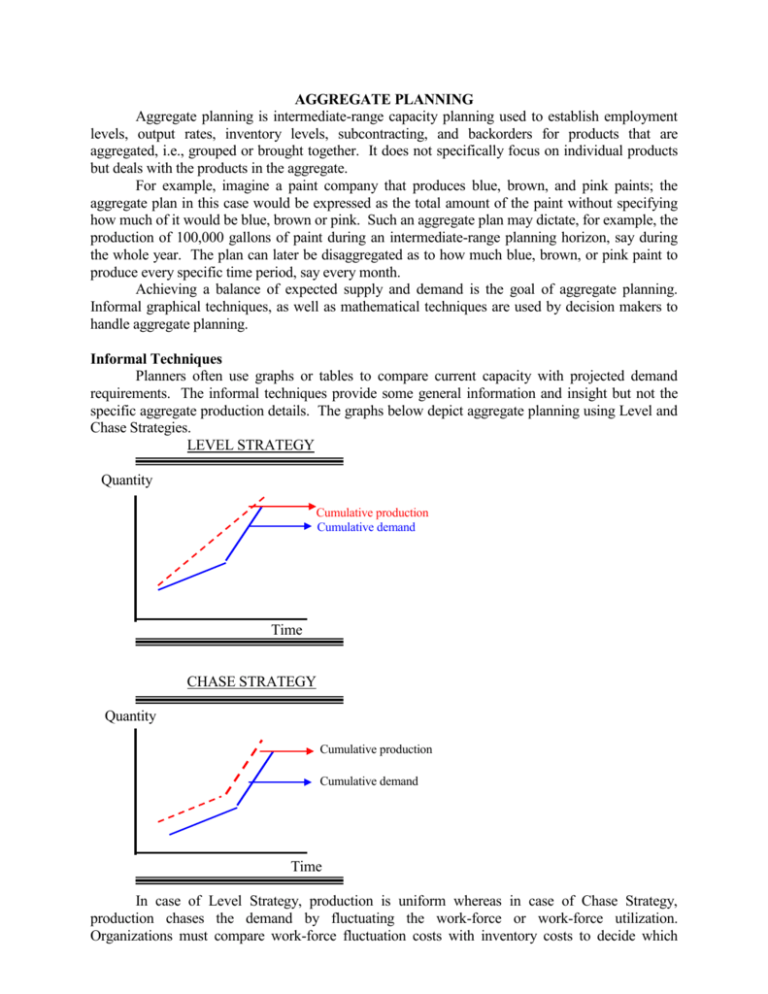

Strategies The broad classes of capacity planning are lead strategy, lag strategy, match strategy, and adjustment strategy Lead strategy is adding capacity in anticipation of an increase in demand Lead strategy is an aggressive strategy with the goal of luring customers away from the company's competitors by improving the service level and reducing lead timeLEVEL STRATEGY A level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment level In the context of the problem posted by you following the level strategy means incurring additional subcontracting costs at least twice This is to offset the shortfall in production because of the level Capacity planning is defined as a method to gauge the production capacity needed to meet the changing product demands of an organization Two terms of design capacity and effective capacity are used extensively in the context of capacity planning The first is the maximum work that is completed in a specific period by an organization, and the latter is the

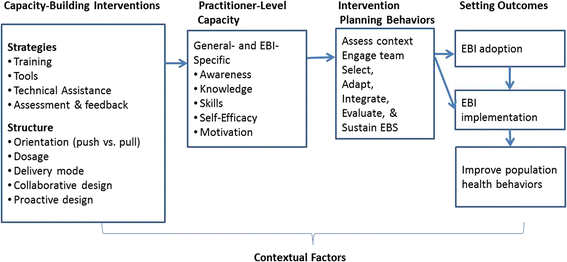

Correct answers 1 question When using a level capacity strategy or level production strategy in aggregate planning, variations in demand are met by using which of the following options? Capacity planning is a strategic process whereby a company determines what level of capacity it will need to satisfy the level of demand for its products or services over a period of timeCapacity development responsibilities under one umbrella to tackle some of the systemic in order capacity constraints and address new capacity emanating from the new programme elements needs This CD Strategy provides a framework to coordinate and implement CD in a systematic and efficient manner

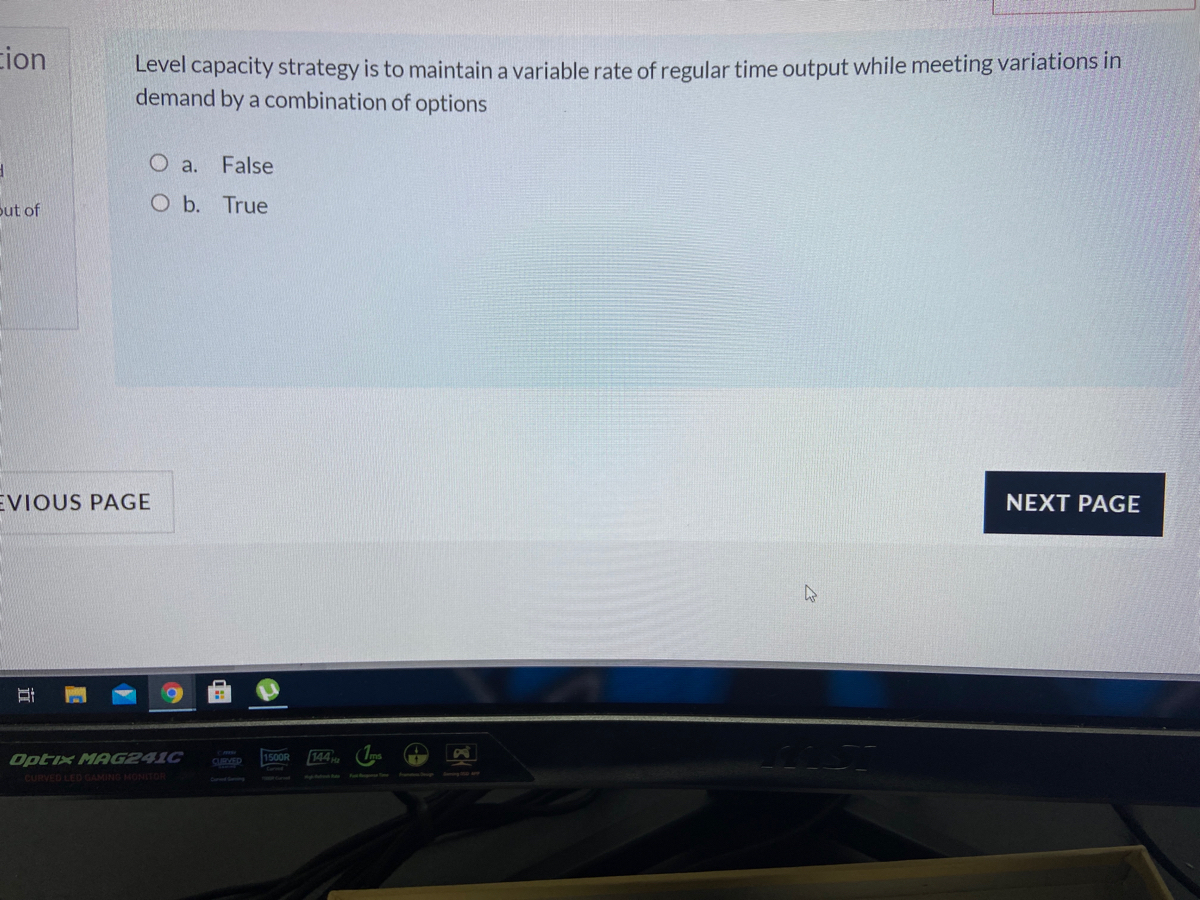

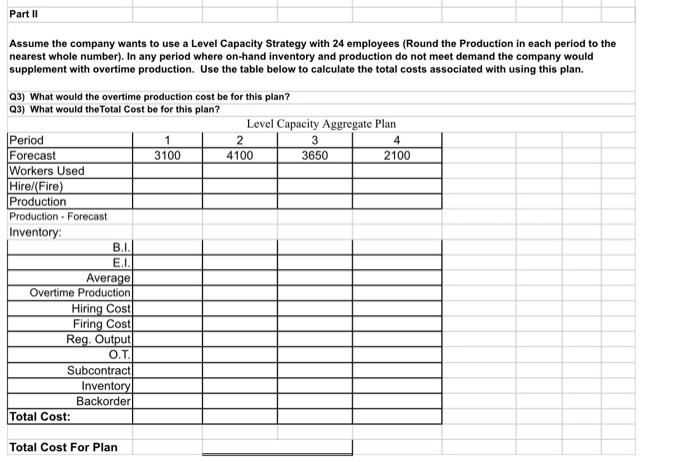

A level capacity strategy is also known An organization can finalize its business plans on the recommendation of demand forecast Once business plans are ready, an organization can do backward working from the final sales unit to raw materials required Aggregate capacity is the total amount of capacity required or available to carry out a function It also tells about the 3 best strategies for aggregate planningThey are level strategy, Chase strategy and hybrid strategy Aggregate planningPlan A – LEVEL CAPACITY STRATEGY (pure) Planning period DEMAND units PRODUCTION PLAN units Regular Inventory Shortages January 0 300 100 February 0 300 0 March 300 0 April 400 300 100 May 500 300 0 June 0 300 1 800 700 100 36 000 4 900 5 000 TOTAL units Partial costs $ TOTAL COSTS = $45 900 100

The Role Of Corporate Controls Size And Corporate Headquarters In The Effect Of Corporate Level Strategy On Business Level Strategy And Business Level Performance Semantic Scholar

3 Types Of Capacity Planning Strategies Valq

The level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to followQuestion in order to use the level capacity strategy, variation in demand are met by select one a using some combination of inventories, overtime, part time, subcontracting and back orders b varying output by changing overtime levels C varying output during regular time without changing employment levels d price adjustments e varyingLevel Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers ( working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventory

Confluence Mobile Innovyze Resource Center

Common Types Of Corporate Strategies Boundless Management

Complexproject, batch production, assembly line and _____? Match strategy is the middle ground between lag and lead strategy Using match strategy, you do strategic capacity planning more frequently You closely monitor true demand, projected demand, and market shifts/trends Based on this information, you adjust your capacity management to meet demand in incrementsLevel capacity strategy enables Capacity planning strategies involve processes used to determine resource manufacturers need to meet demand for their products or services The level of capacity directly related to the amount of output in the form of manufacturers of goods and services can produce to meet customer demand

Productionplanning Aggregate Capacity

11 Capacity Planning And Control Operations Management

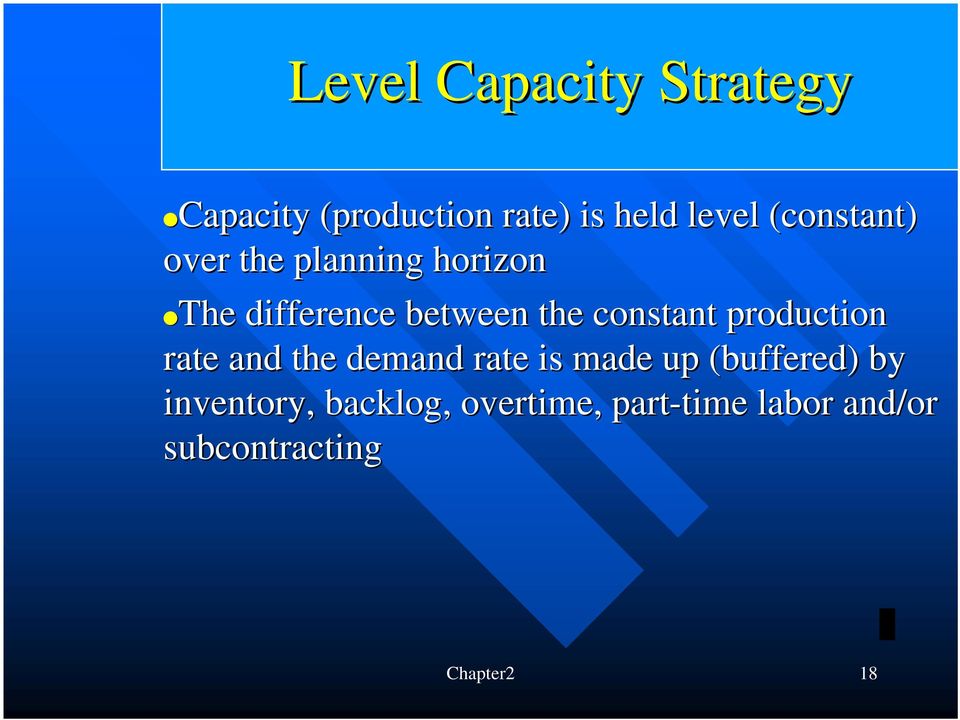

I varying output during regular time without changing workforce size (for example, using overtime) ii varying output during regular time by changing workforce size iii varying inventory levelsLevel capacity strategy Q4 10% Suppose random variable X has a discrete uniform distribution on {1,2,3,,10), ie, X takes x values = 1,2,3,, 10 with probability 01 each Now consider a random binary variable y, with values 1 and Skip to main content Skip to table of content Reference work entryDOI companiesIn this rundown of the juggling feat service managers perform, the author discusses the two basic strategies—"chase demand" and "level capacity"—available to most service companies

Achieving Economies Of Scale Strategy Tools From Mindtools Com

Ppt Chapter 3 Aggregate Planning Steven Nahmias Powerpoint Presentation Id

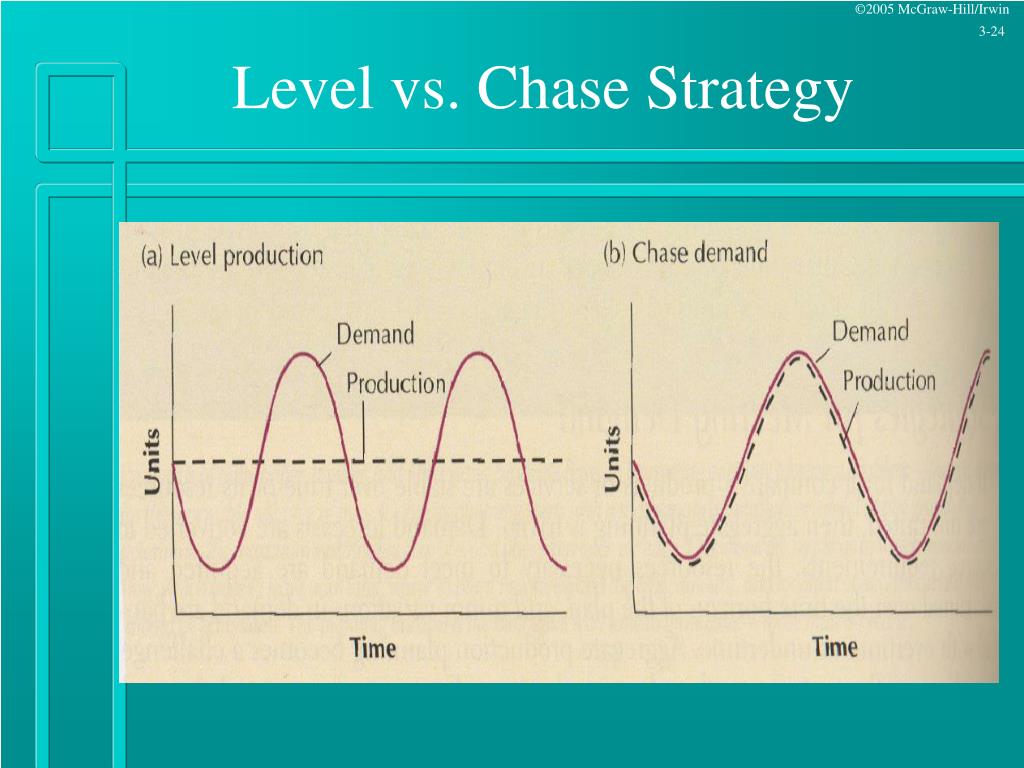

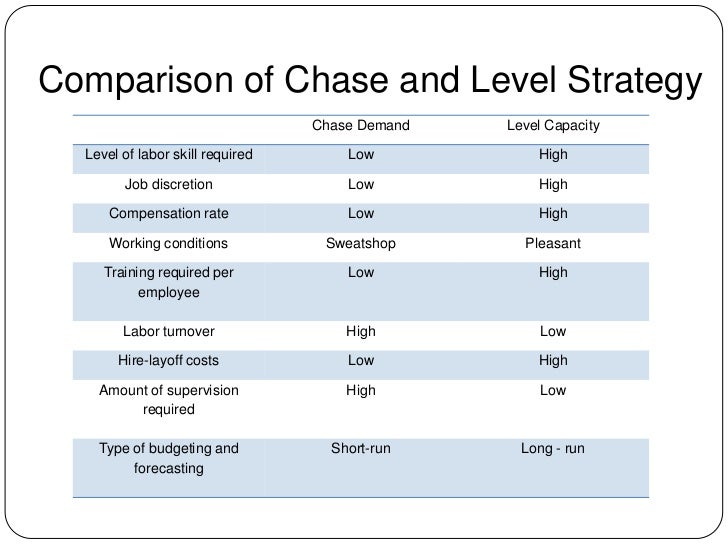

A a level capacity strategy B a demand management strategy c a chase demand strategy d a yield management strategy Discussion d a yield management strategy In the mass production era there were 4 types of operations process;Terms, capacity development includes various approaches, strategies and methodologies aiming at improving performance at different levels Capacity development is a fundamental ingredient of any process of change and transformation, be it individual, organizational, or societalUnder the chase strategy, production is varied as demand varies With the level strategy, production remains at a constant level in spite of demand variations The use of a chase strategy requires that a company have the ability to readily change its output level, which means that it must be able to readily change its capacity

Aggregate Capacity Planning Pdf Free Download

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

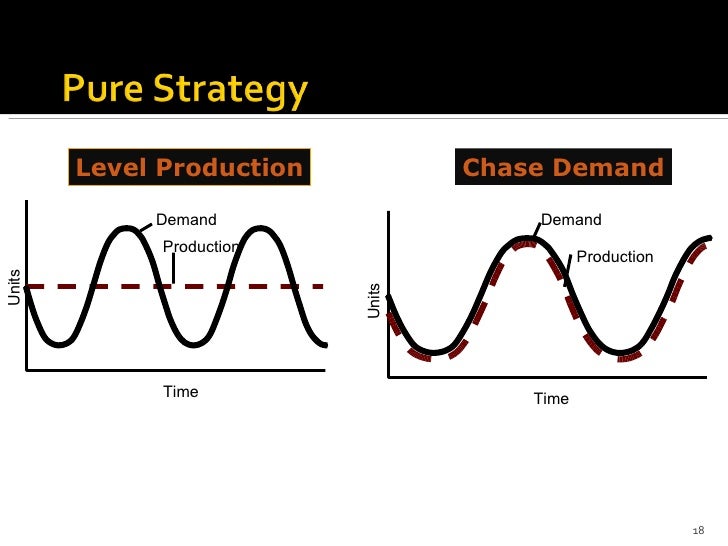

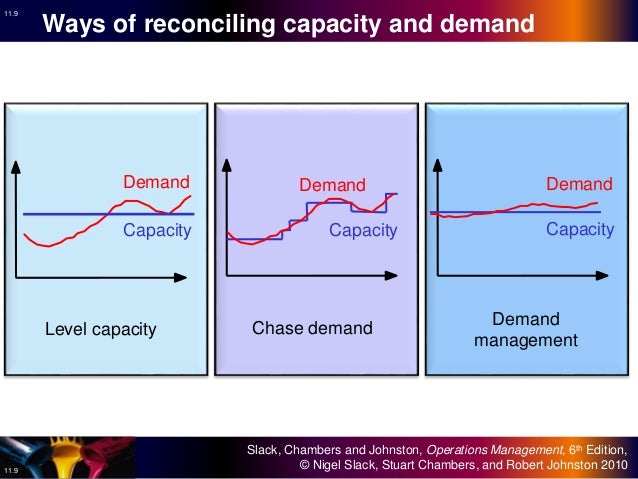

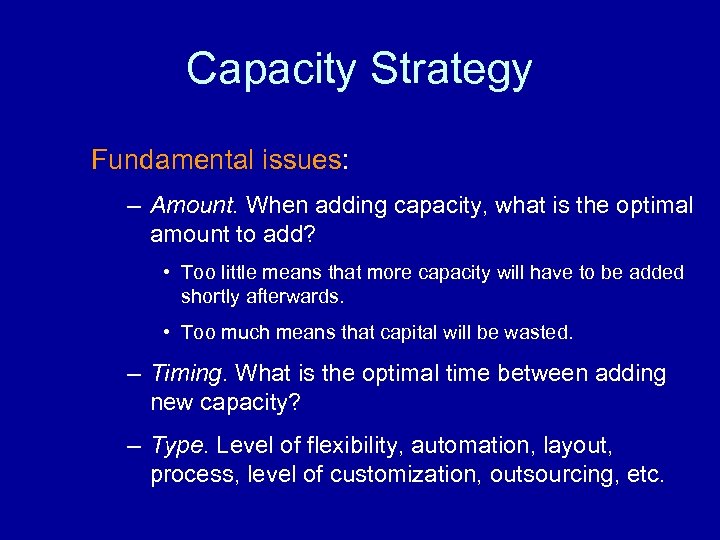

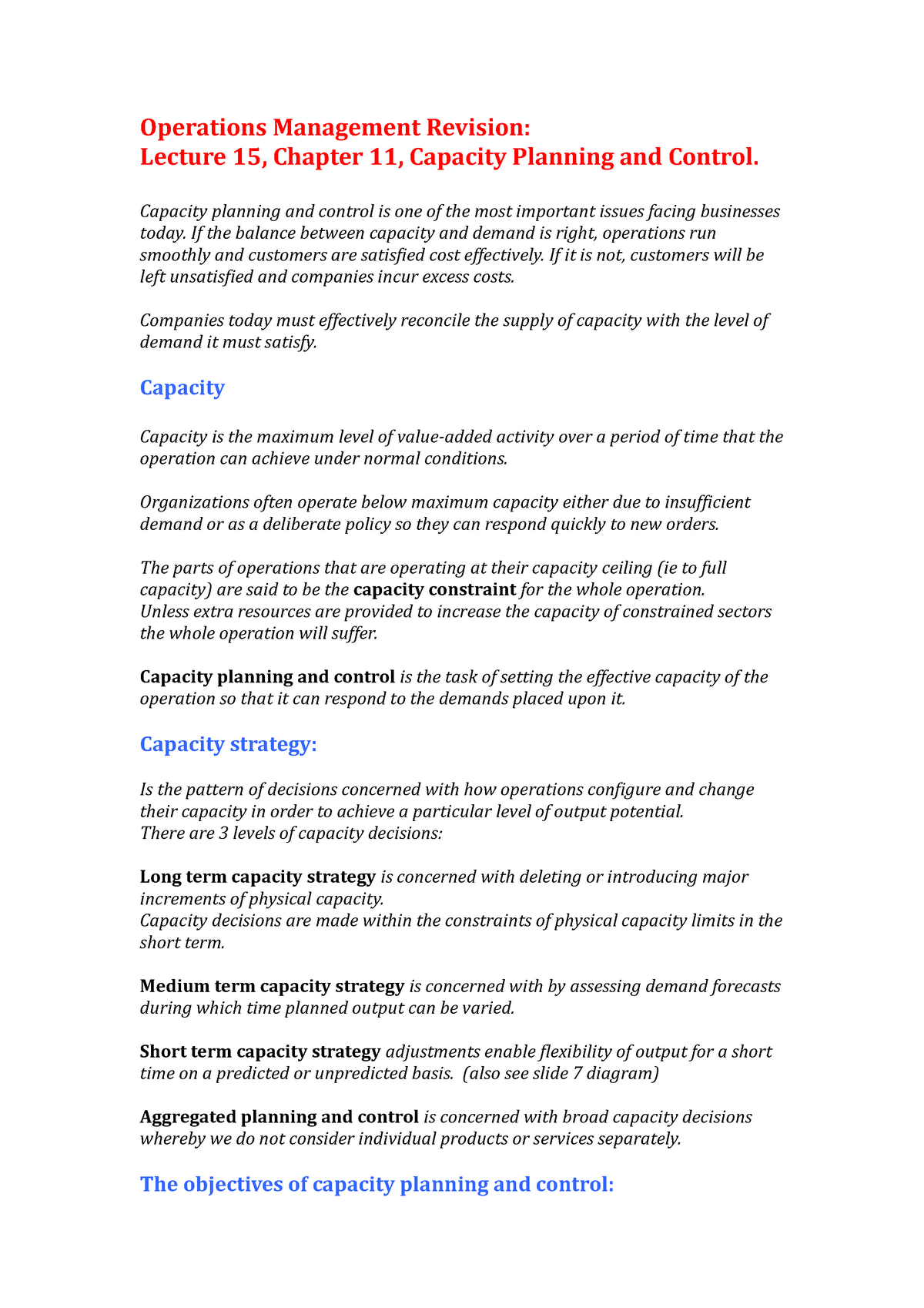

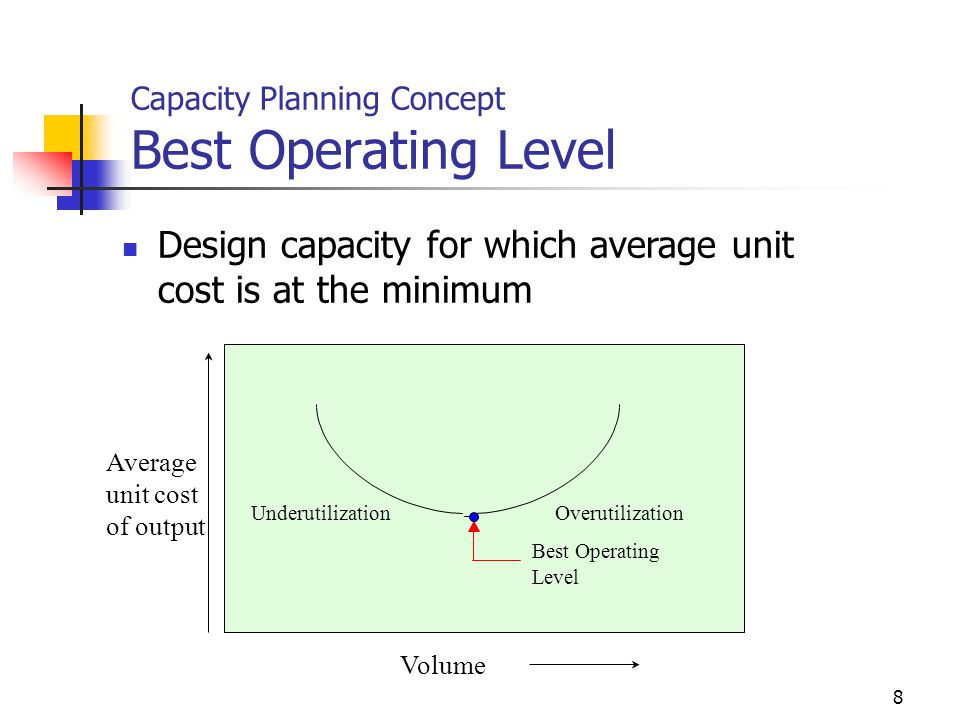

Level Capacity Strategy 1 The utilization of operational resources throughout the year 2 Efficient level of production can be maintained 3 Decreases the marginal cost11 A level capacity strategy is also known as a chase demand strategy Level and chase strategies are opposite approaches 12 An advantage of a "chase" strategy for aggregate planning is that inventories can be kept relatively low The chase strategy keeps inventories low 13 Linear programming models yield the optimal solution Linear programming models can find•Level capacity strategy •Maintaining a steady rate of regulartime output while meeting variations in demand by a combination of options •Chase demand strategy •Matching capacity to demand;

Warehouse Dc Management Inventory Management Requires An End To End Approach Supply Chain Management Review

What Is Capacity Planning Examples Types Optimoroute

There are three commonly recognized capacity strategies lead, lag, and tracking A lead capacity strategy adds capacity in anticipation of increasing demand A lag strategy does not add capacity until the firm is operating at or beyond full capacity For any hotel, airline, restaurant or other service establishment all of the capacity could be filled with customers if the price were low enough But the goal is always to ensure the highest level of capacity utilization without sacrificing profits Heavy use of price differentiation to smooth demand can be a risky strategyIn order to use the level capacity strategy, variations in demand are met by A varying output during regular time without changing employment levels B varying output during regular time by changing employment levels C varying output by changing overtime levels D using combination of inventories, overtime, part time, and back orders

The Impact Of Covid 19 And Strategies For Mitigation And Suppression In Low And Middle Income Countries Science

Supply Chain Control Tower Implementation Approach By Data Labs India Solution Medium

The level capacity strategy involves maintaining stable workforce level and output rates over the planning horizon This allows the firm to maintain inventory levels of finished products higher than expected in situations of low demand variabilityThe use of a level strategy means that a company will produce at a constant rate regardless of the demand level In companies that produce to stock, this means that finished goods inventory levels will grow during low demand periods and decrease during high demand periodsSignificant economic waste, especially manifest in the form of redundant fishing inputs

Capacity Building And Strengthening Framework Pdf Free Download

Operations Management Lesson 8 Flashcards Quizlet

5 CAPACITY MANAGEMENT STRATEGIES 51 Recognizing Capacity Problems Excessive levels of fish harvesting capacity have been held largely responsible for the degradation of marine fisheries resources, the dissipation of food production potential, and; Types of Capacity Planning Strategies 1 LEAD STRATEGY The Lead Strategy involves an upfront investment in more capacity that is needed and is one of the 2 LAG STRATEGY The Lag Strategy is much more conservative than the Lead Strategy as it waits until the current 3 MATCH STRATEGY TheCapacity Planning Approaches There are four principle methods to approach capacity planning Each method is based on reacting to or planning for market fluctuations and changing levels of demand These capacity planning strategies are match, lag, lead, and adjustment Match

Capacity Planning Meaning Classification And Its Goals

Everything You Need To Know About Material Requirements Planning Mrp Smartsheet

Lead Strategy An upfront investment in more capacity that you need This can be done when capacity is inexpensive or difficult to obtain For example, a new vineyard anticipates using less than 10 acres of land in its first 5 years but purchases 100 acres of land as a long term investment in the businessUse break even analysis to evaluate capacity alternatives This module examines how important strategic capacity planning is for products and services The overall objective of strategic capacity planning is to reach an optimal level where production capabilities meet demand Capacity needs include equipment, space, and employee skillsLevel Strategy It is to be used when the same quality and quantity of the production procedures are required Chase strategy It is to be used when there is variation in the order capacity or

Strategic Capacity Planning Introduction To Operations Management

Chapter 13 Production Planning Supplemental Slides 1 Overview

The level production strategy, shown in Figure 114(a), sets production at a fixed rate (usually to meet average demand) and uses inventory to absorb variations in demand During periods of low demand, overproduction is stored as inventory, to be depleted in periods of high demand The cost of this strategy is the cost of holding inventory, including the cost of obsolete or perishable itemsExplain about the level capacity strategy, Operation Management Explain embedding knowledge, "Embedding Knowledge" Please respond to the fo Explain forecasting methodologies, Question What are the common chara Question What are the The primary difference among the three strategies is the lever, that is, the parameter that is manipulated to achieve equality of supply and demand over the aggregate planning period The first chase strategy uses capacity, in the form of machine or personnel capacity, as the lever

4 Capacity Strategy

Planning Demand And Supply In A Supply Chain Forecasting And Aggregate Planning Chapter 8 1 Utdallas Edu Metin Slideshow And Powerpoint Viewer Aggregate Planning Ag Gregate Past Part Of Ad Gr

The planned output for a period is set at the expected demand for that period 3 Hybrid strategy for an aggregate planning As the name indicates, the Hybrid strategy is an integration of both level and chase strategies to get a better result It maintains a sufficient balance between stock level, recruiting, termination and production rateПроизводство стратегия постоянного уровня производства

Impact Of The Level Of Reactive Capacity On The Protability Of Download Scientific Diagram

Solved Question 26 Level Capacity Strategy Is Considered Chegg Com

Level capacity strategy One of the trickiest aspects of running a production plant is determining exactly how much to produce, when to produce it, and what supplies need to be ordered and when Failure to have the product to fulfill orders erodes buyer confidence, but having too much supply on hand is risky for a variety of reasons

Strategy Under Uncertainty

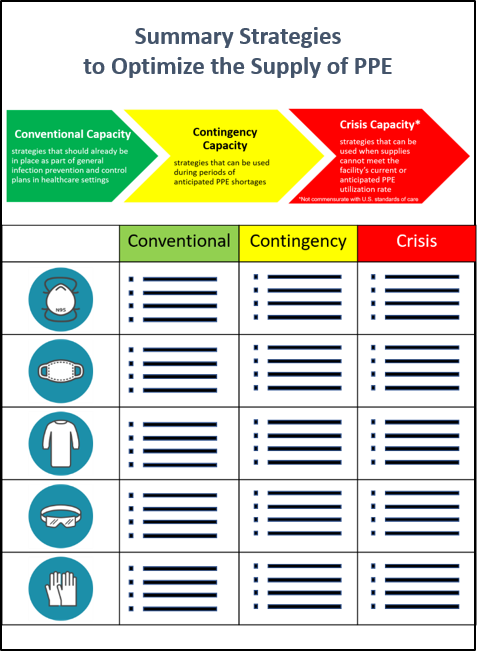

Covid 19 Strategies For Optimizing The Supply Of Ppe Cdc

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Jones Robinson Operations Management All Operations Need To Know The Likely Customer Demand For Their Goods Or Services On Any Given Day Week Or Year Ppt Download

Capacity Strategy Some Factors Influencing The Overall Level Of Capacity Forecast Level Of Demand Consequences Of Over Under Supply Availability Of Ppt Download

Multi Level Model For Building Capacity For A National Quality Download Scientific Diagram

Capacity Management Studocu

12 1 Aggregate Planning Operations Management William J

Ability Capability Capacity And Competence Bpi The Destination For Everything Process Related

Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Sciencedirect

Aggregate Production Planning Operations Management Homework And Assignment Help

A Current Issue In Production Operations Management By Jennifer Feng

Everything About Capacity Planning Strategies Its Benefits

Uninote Ecommerce S3 Eu West 2 Amazonaws Com Capacity management Pdf

Www Morningstar Com Content Dam Marketing Shared Research Foundational Evaluating Capacity And Liquidity For Equity Strategies Dec18 Pdf Cid Emq 8037

Capacity Planning Online Presentation

The Emergence Of Absorptive Capacity Through Micro Macro Level Interactions Sciencedirect

Roadmap Scaled Agile Framework

Processes Technology And Capacity Online Presentation

Multi Level Model For Building Capacity For A National Quality Download Scientific Diagram

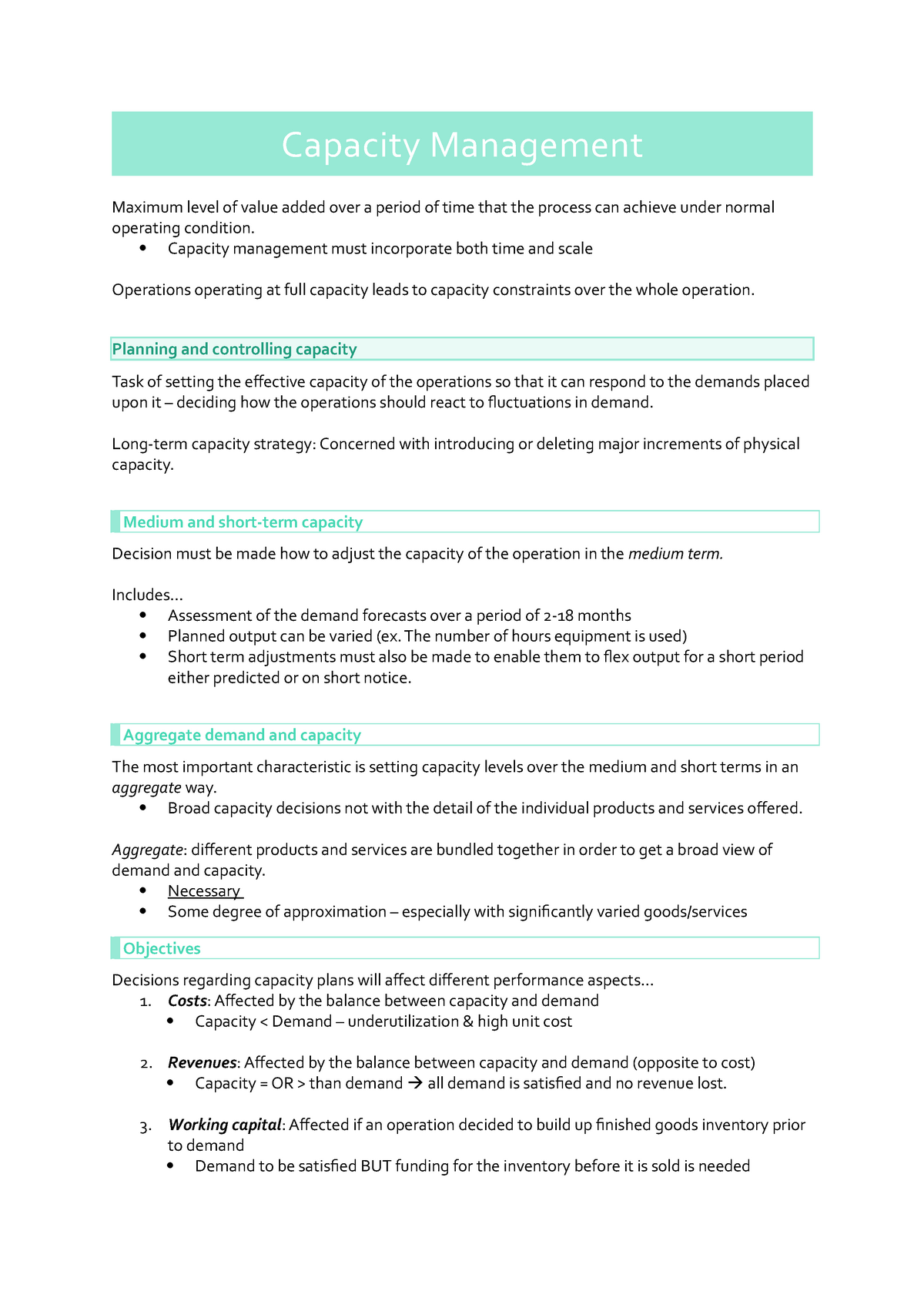

Mcq S Week 7 Capacity Management Chapter Week Capacity Management Which Of The Studocu

Competitive Advantage Tutor2u

3

Answered Level Capacity Strategy Is To Maintain Bartleby

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

How Cement Companies Create Value The Five Elements Of A Successful Commercial Strategy Mckinsey

Is Muni Cz El Econ Jaro09 Phom Um Chapter 11short Pdf

What Is Capacity Planning Examples Types Optimoroute

Capacity Strategy Economies Of Scale Strategic Management

Everything About Capacity Planning Strategies Its Benefits

Part Ii Assume The Company Wants To Use A Level Chegg Com

4 Levels Of Service

Entries For Thursday 25 October 07 Sergio S Blog

Ie 3265 Production Operations Management Slide Series

Operations Management Ppt Video Online Download

Capacity Management Process Pink Elephant United Kingdom

Lecture 15 Chapter 11 Capacity Planning And Control Studocu

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Evaluating Alternative Capacity Strategies In Semiconductor Manufacturing Under Uncertain Demand And Price Scenarios Sciencedirect

Production Planning Control Chapter 2 Aggregate Planning Master Production Scheduling Chapter2 1 Pdf Free Download

When Using A Level Capacity Strategy Or Level Chegg Com

Capacity Management

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

Aggregate Planning Planning Horizon Aggregate Planning Intermediate Range

What Is Capacity Planning Examples Types Optimoroute

Myclass Dau Edu cswebdav Xid 4 2

Demand And Capacity Management Options Adapted From Fitzsimmons And Download Scientific Diagram

What Strategies Are Used To Build Practitioners Capacity To Implement Community Based Interventions And Are They Effective A Systematic Review Implementation Science Full Text

Operations Strategy Capacity Strategy Ppt Video Online Download

Strategic R D Portfolio Management Vs Operational Capacity Planning A Tale Of Two Disciplines Enrich Consulting

Sales And Operations Planning Aggregate Planning Production Planning

Demand And Capacity Management Options Adapted From Fitzsimmons And Download Scientific Diagram

The Dynamic Synchronization Of Strategy And Information Technology

The Future Of Strategic Operations Management

Covid 19 Decontamination And Reuse Of Filtering Facepiece Respirators Cdc

3 Types Of Capacity Planning Strategies Valq

3 Types Of Capacity Planning Strategies Valq

Using Expanded Real Options Analysis To Evaluate Capacity Expansion Decisions Under Uncertainty In The Construction Material Industry

1

Chapter 11 Aggregate Planning And Master Scheduling Chapter

Optimal Capacity And Price Levels For Different Capacity Investment Download Scientific Diagram

M Dc Operations Strategy

Aggregate Planning Report

Is Muni Cz El Econ Jaro09 Phom Um Chapter 11short Pdf

Demand And Capacity Planning In The Emergency Department How To Do It Emergency Medicine Journal

11 Managing Resources Flashcards Quizlet

Consultation On Gnc Draft Capacity Building Strategy Nutrition Cluster

Pdf Lean Capacity Planning Planning For Maximising Customer Value Semantic Scholar

3

Lecture 7 Production Planning System Revisited Books Introduction

Www Open Ac Uk Centres Policing Sites Www Open Ac Uk Centres Policing Files Files News An evaluation of demand Management Practices In Uk Final Report Pdf

Aggregate Planning

Slides For Chapter 10 Strategic Capacity Honda On July 18 Announced Two New Plants In Argentina Honda Will Spend 100 Million On A New Compact Car Ppt Download

Ppt Capacity And Scheduling Management Powerpoint Presentation Free Download Id

1

Michelle Barker She Her My Blog On Our Oecd Report On Digital Workforce Capability For Research Highlights A Recommendation Applicable To Any Organisation Community To Evaluate And Improve Their Digital Workforce Capacity

Capacity Planning Types Lead Lag Average Strategies Video Lesson Transcript Study Com

Monitoring And Evaluation Of Brazilian South South And Trilateral Cooperation Sstc On Capacity Development And Social Protection Learnings From The Field Socialprotection Org

Roadmap Scaled Agile Framework

Aggregate Planning

0 件のコメント:

コメントを投稿